4-Way Roller Fairlead

ITEM NO: PN45SPEC: Adapted to 2000lb 180001b winches with steel cableA 4-Way Roller Fairlead is a component used in winching operations. It is typical...

ITEM NO: PN45SPEC: Adapted to 2000lb 180001b winches with steel cableA 4-Way Roller Fairlead is a component used in winching operations. It is typical...

ITEM NO: PN46SPEC: Adapted to 2000lb-18000lb winches with synthetic ropeAn Aluminum Hawse Fairlead is a type of fairlead used in winching applications...

ITEM NO: PN59SPEC: Wireless receiver uses the same port as the LIFT wired hand remoteThe 'Plug N Play' Wireless Remote Kit is a convenient accessory f...

ITEM NO: PN048SEPC: Fits 6000-20000b electric winchesA wired switch for a 4x4 winch is a control device used to operate the winch. It includes a handh...

ITEM NO: PN050 PN051SPEC: PN050: Fits for external receiver PN051: Fits for internal receiverA wireless switch for a 4x4 winch is a remote co...

ITEM NO: PN054 PN055 SPEC: Fits P2000-1,P2500-1 ,P3000-1 series ATV/UTV winchA wired switch control box is a device used to control various functions ...

Founded in 2004, Ningbo Lift Winch Manufacture Co., Ltd.(Old Name: Ningbo Yinzhou Dongfeng Power Tool Factory) has more than 20 years of experience in winch manufacturing. We are a professional Winch Accessories manufacturers and Winch Accessories factory for custom off-road vehicles, utility vehicles, ATVs, boats and yachts, etc. We provide a wide range of electric winches from 1500lbs to 20000lbs, hand winches, and custom off-road accessories.

Equipped with superior production facilities, we have sophisticated inspection methods, a strong R&D force, and strict&effective quality control system. We specialize in Custom Winch Accessories, We have CE and FCC approval and we are certified for our quality management system conforming with ISO9001 standard.

We have been dedicated to improving our production and R&D capability to perform perfectly our service conception of "High Standards, Strict Requirements, High Quality". Our products are widely exported to Europe, America, Oceania, the Middle East, etc, and are well received by auto wholesalers, supermarkets, and off-road vehicle manufacturers.

We sincerely welcome clients from all around the world to visit and cooperate with us!

We have CE and FCC approval and we are certified for our quality management system conforming with ISO9001 standard.

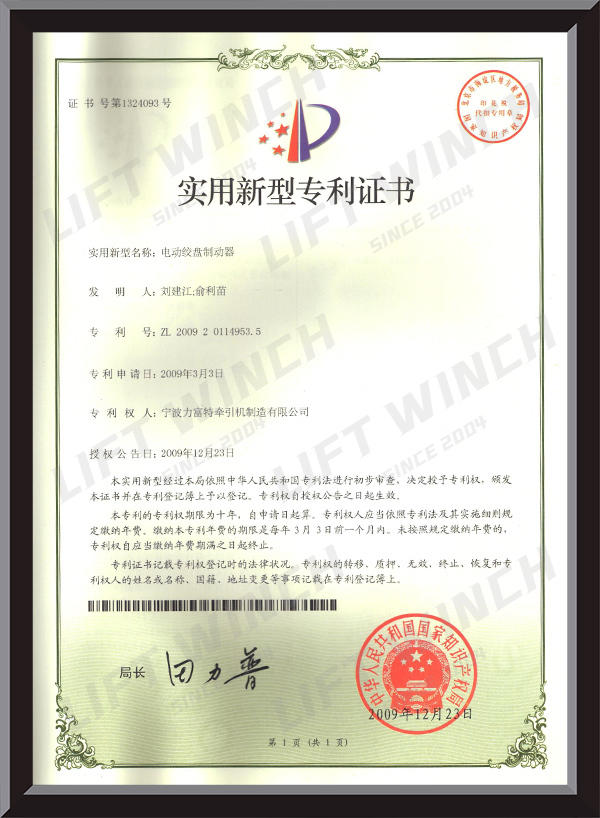

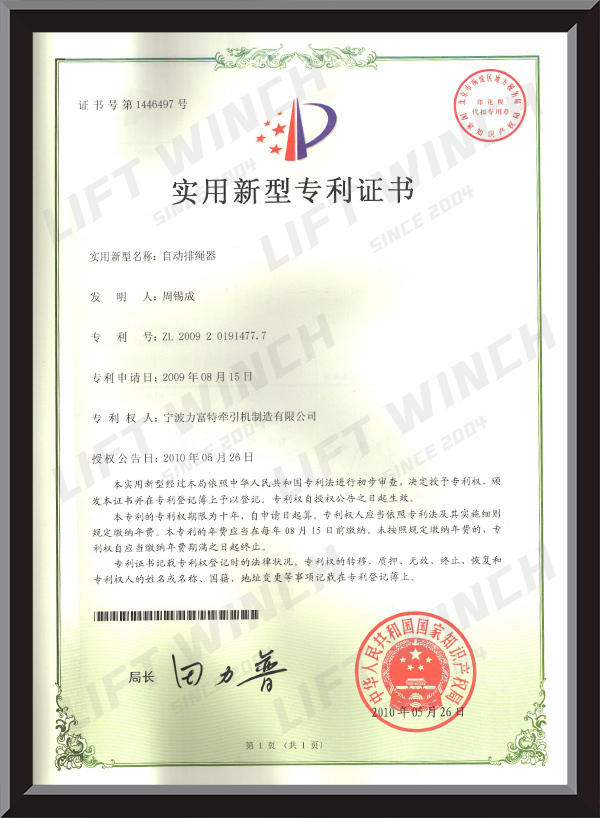

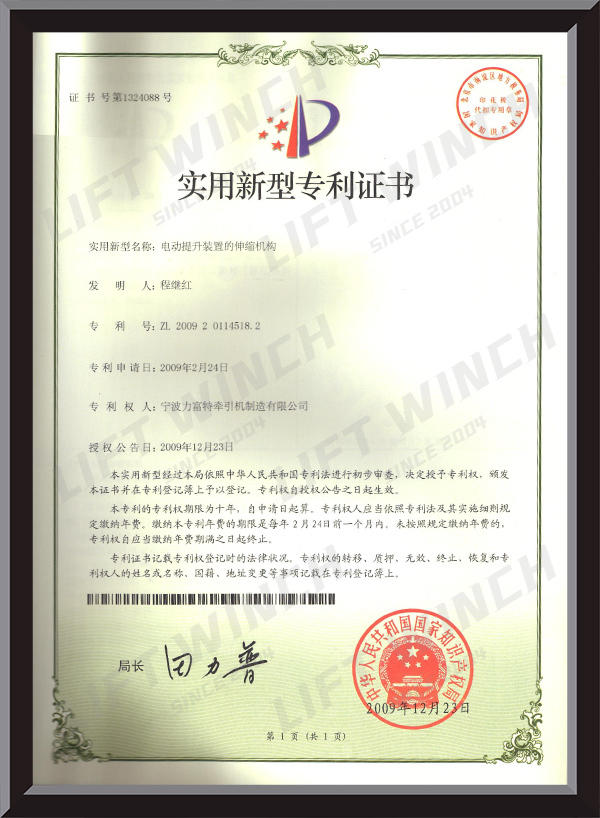

Patent

Patent

Patent

Patent

Patent

EMC

TCB

SGS

SGS

CE

In rescue and emergency situations, time is of the essence. Therefore, efficient, reliable and durable rescue equipment is crucial. Synthetic Rope, a ...

Hand winches have long been used as the primary pulling device in ship transportation and towing operations. However, with the advancement of technolo...

As a key guiding component of a tow rope or cable, the selection of the Roller Fairlead is critical, especially when load and pull requirements are ta...

In the field of marine engineering and shipbuilding, Bow Shackle plays a vital role as an important connecting piece. Its unique design and superior p...